Electrical Insulating Rubber Matting IEC/BS EN 61111:2009

Vardhman Insulating Matting (Di-Electric Carpets) made of Rubber Compound suitable for providing the Electrical safety to the workmen working around the possible areas of Electrical shock and act as a safeguard equipment from electrical shock due to leakage of current, shot circuit or any other.

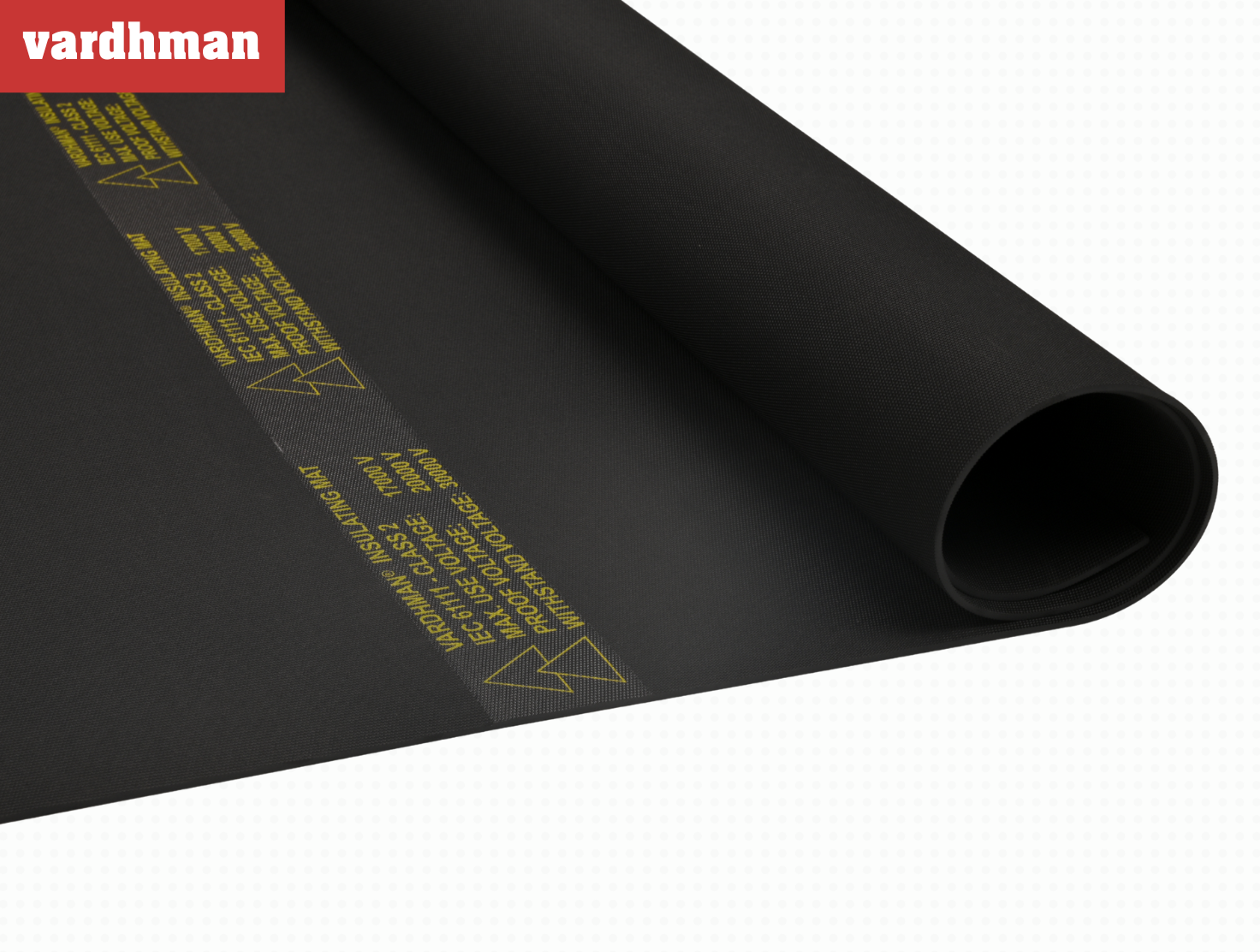

Electrical Rubber Matting manufactured by Vardhman conforms to IEC 61111 and comes with a double triangle logo. The special high quality Rubber Compound ensures the complete shock protection against electrical shocks due to electrical earth faults.

Our Mats are fully compliant With IEC 61111 (International Electro Technical Commission) and are regularly tested by third like TUV, Lloyds and many others. The mats offered by us are ROHS and PAH Compliant.

We at Vardhman, adopt the most advance technology to manufacture Insulating Mats. The state of the art line (German Technology) makes our quality and finish unmatchable in the industry.

All the testing and inspection facilities are established within the factory Which ensures every square inches of mat are fully tested to the specifications.

Key Features

IEC 61111 Certified

Fully tested to specification IEC 61111 with double triangle logo for international compliance.

High Electrical Resistance

Up to 50 KV/50000 volts of electrical resistance for maximum safety.

Flame Retardant

Health and safety regulation Halogen Free flame retardant material.

Anti-Slip Finish

Tested to slip resist test with self-gripping design on floor.

Chemical Resistance

Resistant to acid, oil and passes low temperature test.

Weather Resistant

Ozone, UV and weather resistant for long-lasting performance.

Applications

Electrical Panels

Used in front and rear side of electrical panels for worker safety

Switchgears

Provides protection around high voltage switchgear installations

Transformers

Essential safety flooring around transformers and substations

Portable Protection

Used as portable protection for site engineers working on live equipment

Technical Specifications

*Specification are subject to change without prior notice.

Selection Guidance

For Low Voltage Applications (up to 1000V)

Recommended Product: Class 0 - 3 mm thickness (Red)

Ideal for low voltage environments with proof voltage of 5000V.

For Medium Voltage Applications (up to 7500V)

Recommended Product: Class 1 - 3 mm thickness (White)

Suitable for medium voltage environments with proof voltage of 10000V.

For High Voltage Applications (up to 17000V)

Recommended Product: Class 2 - 3/6 mm thickness (Yellow)

Designed for high voltage environments with proof voltage of 20000V.

For Very High Voltage Applications (up to 26500V)

Recommended Product: Class 3 - 4/6 mm thickness (Green)

Designed for very high voltage environments with proof voltage of 30000V.

For Extremely High Voltage Applications (up to 36000V)

Recommended Product: Class 4 - 4/6 mm thickness (Orange)

Designed for extremely high voltage environments with proof voltage of 40000V.

Benefits of Choosing Our Electrical Insulating Rubber Matting

IEC 61111 Certified

Full compliance with international standards for electrical safety equipment.

German Technology

State of the art manufacturing line with German technology for unmatched quality.

Thoroughly Tested

Regularly tested by third parties like TUV, Lloyds and others for quality assurance.

ROHS and PAH Compliant

Environmentally friendly materials that meet international safety standards.

Customization Options

Available in various sizes, colors, and thicknesses as per specific requirements.

Technical Support

Expert guidance from our experienced team for selecting the right product.

Confirm Marking

The marking on the top side (always visible) of the safety mat will consist of following details: The complete marking shall be marked at least once on every meter of mat. The marking shall be colour coded as per IEC 61111:2009 guidelines.

Need a solution for your specific requirements? Contact our team with your application details so we can recommend best solution tailored to your needs.